Hers.

Here’s the story of what happens when I go out of town for a few days, leaving Chris behind. When having a spare weekend without the ole ball and chain, some husbands call up their friends for an epic guys’ night, some commandeer the TV for a 24/7 Sports Center marathon (sadly, I know that’s a thing as my brothers would watch the same episode of SC over and over again until they could parrot it back), and some may even decide to go on their own trip to hunt, camp, or some other bug-infested, manly activity that makes wives shudder at the thought.

So, what does my husband do? Something a tad different. He turns into the Extreme Home Hulk-Over… aka goes into full demo mode.

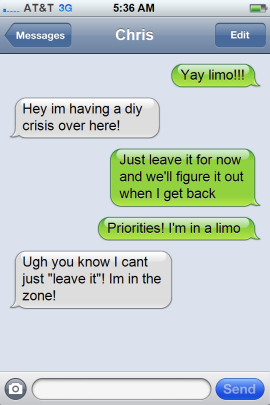

Yup, Chris went all super-Hulk on our laundry room. And he felt the best way to warn me of his work was with the below text. Husbands, listen up, here’s how not to break the news to your wife that you’ve gone rogue.

Yes, it appears that we were about to venture into phase 2 of the laundry room makeover (um, I didn’t quite realize we even needed a phase 2 but apparently I was wrong). But let’s catch you up a little, shall we? We revealed our dramatic laundry room makeover nearly a year ago (read more here). Short version?

We went from this:

Ah, and of course my dirty little secret stash hidden behind the door.

The door always stayed open for two reasons- 1) to easily unload the dryer which was a front loader and 2) so Chloe, our cat, could easily access her litter box which was in the right-hand corner. This drove Chris N-U-T-S- he wanted that door closed so it would help contain the machine noise and Chloe’s less-than-stellar smelling litter. He even proposed we cut out a doggy door so we could close the door and Chloe could still get in. Um, no, honey, we’re not installing an interior doggy door. I’m pretty sure that would automatically lump us in with the crazies on Animal Hoarders (no lie, I recently saw an episode that had a doggy door installed between each room of the house so the cats didn’t have to be inconvenienced by walking out of one room, down the hall, into another room… who does that?!).

So the door stayed as-is until… (fast forward to me being out of town) Chris installed our new washer/dryer set and discovered that the new dryer stuck out further and was impossible to access with the door open.

As I’m enjoying my trip and the free limo involved, my phone is being bombarded with DIY SOS’es. Husbands, daily lesson #2 for you: seriously, don’t mess with your wife’s free limo time.

I’ll give you one guess on if you think he left it alone until I got back…

Well, here’s the first thing I saw leaning against the back of our house upon my return.

Because I know my husband and pretty much knew I’d be coming back to a doorless laundry room, I started digging into a potential solution. No way was I going to leave the space open. As cute as our teal cabinets are, I wanted to be able to close off this space. Chris suggested a bifold door but I’m not the biggest fan of bifolds and I knew it would still drive Chris crazy because I’d still never close it due to Chloe.

And then a genius idea struck. Finally, a way to put all those barn door inspirations I pinned on Pinterest to good use! This would be the perfect space for a barn door! It would slide across a track on the exterior so I could leave it open a crack for Chloe to get in and it would be a huge statement piece for that hallway.

Ah, such beauty. We had a plan and were off!

And then I discovered how much barn doors were aaand Chris hit the brakes on the project. He wasn’t too keen on dropping $500-700 on an old busted up door that he claimed anyone could just build. “But it’s so full of character!” I argued. That didn’t get me too far. It was time to switch tactics.

“Well, hon, if anyone could just build it, why don’t you?” Bingo. But I wanted a barn door as genuine as possible (even if it wasn’t originally intended for a barn) and that meant genuine barn wood. If you haven’t priced out barn wood lately, let me catch you up on how expensive it’s become. Expensive as in $8. Don’t make the

We did find an awesome deal on reclaimed cedar planks, however (seen on the far left of the above picture). Meh, close enough… especially considering it was only $1/foot (which ended up being $8/board). Not too bad considering they sell new for $15 per board at home improvement stores.

And now for Chris to work his magic and convince me that building a barn door really wasn’t all that tough. We’ll see, Hulk, we’ll see.

His.

If you read this blog regularly, you know my feelings toward doors: they make me angry. And you wouldn’t like me when I’m angry. Sometimes I want to study quantum physics just so I can try to invent a way to eliminate the need for them entirely.

Now, by far the stupidest door in our house was our laundry room door. It was a 30″ door in a 10 sq. ft. room. For the conversion-impaired, that means that the space required for the door to swing open was 25% of the room. 25%! What idiot drew up those plans and thought, “yeah that’s an acceptable thing”? Now I understand that the doorway has to be a particular width in order to be able to fit the laundry machines in, but it’s clearly not a room where a hinged door is a sensible solution.

For a while we were somewhat content to just leave the door open, but our machines operated somewhere just shy of permanent hearing loss noise levels and the cat’s “business” can often be detected three counties away. It wasn’t until my parents gave us their old machines (thanks, Mom and Dad!) that a solution was actually required- the new machines’ plumbing cause them to stick out much further into the room, and since they’re both front-loaders you couldn’t even get them open. So now we had yet another problem with this door, and this time a solution really couldn’t wait but since the decision-maker was out of town, I had no choice but to rip it off the hinges.

Fast forward a few days and we stood in front of the doorway, pondering our newfound dilemma. The more I thought about it, the more I realized just how many sensible options the builder had: a pocket door, bifold doors, double doors, etc. But, of course, they went with the option that minimized usable space in the room. And to make matters worse, every reasonable alternative I could think of would require major “modifications” to the wall, and frankly I’d rather have no door than to have to replace a wall.

And then it hit me: a barn door. Julie has been droning on for a few years about how she “dreams of having a barn door someday,” so getting her on board was a cinch. At the time I didn’t know much about barn doors but I had seen a few pictures and they looked simple enough, plus I know that in the old days a farmer would have probably built his own barn and wouldn’t waste much time on perfecting a door, so it couldn’t possibly be that complicated.

And it’s really not.

For the most part, a barn door is just a bunch of square cuts nailed together in specific dimensions. Julie picked out some antique siding that I planned on using as the “background” of the door, but after seeing the prices they wanted for actual antique barn lumber (something like $8 per linear ft…. yeah, right), I convinced Julie I had a much better solution: cedar.

I guess it’s intended for pergolas and fences, but these 2x6x8 boards were the perfect fit for our project, having just the right level of “rawness” to pull off the look we were going for, but were still quality cuts that were easy to work with. And for $8/ea they seemed like a steal:

The only problem with these is that they can vary pretty wildly in color, and we needed three pieces that not only matched each other, but also matched the antique siding we bought. So I crawled around the lumber section showing Julie board after board trying to find a winner. The kid working there kept asking if we needed help, but frankly I think we’re beyond help with these things.

Approximately one eternity later, we had all the pieces we needed for the project. I cut two of the 2×6 cedar pieces to the overall height of the door, which for this application was 7′ (we had fairly thick trim that we wanted to cover). For the cross pieces, I just cut three pieces of uniform length. I was building a door that was 30″ wide, so the cross pieces were 30″ – 2x the 2×6 width (remember, 6″ is the width of a 2×6 BEFORE it’s milled, so it’s usually closer to 5.5″). Obviously two of the cross pieces went at the top and the bottom, but there was a bit of a debate as to where the middle piece would it go: the geometric middle, or the height at which the handle would go, which was bascially 1/3 the total height of the door. Well, we ultimately agreed that an asymmetrical look was what we really wanted, so the middle piece went at 1/3 the overall height of the door.

To put everything together, I used two types of brackets, 90* on the backside and straight brackets on the top and bottom:

Why the 90* brackets, you ask? Well, I didn’t want any pieces to sag over time; using a 90* bracket ensures that the downward forces are applied at an angle rather than straight down, reducing the risk of any separation at the seams. The straight brackets at the top and bottom were for added rigidity, especially when moving the door around during construction.

Next, I had to put the siding together across the back of the door to created the “background” for the barn look. The only difficult part of this was that I was actually assembling it atop a pair of sawhorses and everything was technically upside down. I glued everything down with wood glue (which was probably overkill) and then finished it off with my trim nailer:

So now I had a pretty basic door. The wood was rough so we sanded it down to avoid splinters:

Unfortunately, I wasn’t done quite yet. Julie also wanted a diagonal piece, so I used a cedar 2×3 and traced out the angles across the door sections:

So, put it all together and what do you get? A barn door! That isn’t from a barn…

Supply and Cut List:

- Two 2×6 cedar boards – cut to 7′ long for the sides. Purchased two at $9.97 each.

- Three 2×6 cedar boards – cut to 19″ long for the top, bottom, and middle. Purchased one board to cut three pieces from at $9.97 each.

- Two 2×3 cedar boards – used for the crossbeams. Purchased one piece to cut two pieces from at $3.97 each.

- Four old cedar siding planks – cut to 7′ long to make up the base of the door. Purchased four planks at $1/linear foot or $8 each.

- Four right angle brackets – to hold the side boards to the top and bottom boards.

- Two T-brackets – for center board.

- Four straight brackets – two for the top board and two for the bottom.

- Wood glue – already had on-hand.

- Nails – already had on-hand.

- Handle. $3.28.

Cost Breakdown:

- Wood: $65

- Brackets: $5

- Handle: $3

- Total: Just under $75

Click here to watch the sparks fly as I twist raw steel into some sweet custom barn door hardware!

After.

And here’s where we tell you how the door debate is now over. Right? Not quite.

Here’s the door when Julie passes through.

And here’s a reminder of where we started. Pretty amazing how one door can transform a space so dramatically, huh?

Stay tuned for the breakdown of the door hardware and track build!

Original article and pictures take http://doordiy.wordpress.com/2014/01/26/when-the-wifes-away-the-hulk-will-play/ site

>

Комментариев нет:

Отправить комментарий